NON-REINFORCED

ELASTOMERIC BEARING

ELASTOMERIC BEARING

Optimum construction work quality guaranteed

Permanent loads, such as a structure's dead load, variable influences, such as wind, and constraining forces due to factors such as temperature changes, creep, component tolerances or settling cause deformations in structural components. The aforementioned influences inflict damage to structures if no suitable elastomeric bearings are used. Besides cracks and spalling, they can also cause major permanent damage to adjacent components, which will then need to be repaired at considerable expense in terms of time and cost.

The elastic effect of the structural bearings transfers forces centrally in structural connections while also compensating for deviations in plane parallelism. Elastomeric bearings systematically absorb shear deformations from non-permanent horizontal impacts.

The elastic effect of the structural bearings transfers forces centrally in structural connections while also compensating for deviations in plane parallelism. Elastomeric bearings systematically absorb shear deformations from non-permanent horizontal impacts.

Advantages for our customers

The bearings’ extremely high load capacities allow cost-effective, filigree structural designs to be built. Elastomeric bearings do not require maintenance and do not need to be replaced if correctly dimensioned and installed. The designers also ensure there is extra capacity in the material to absorb unforeseen loads. The service life of construction bearings is equal to the service life of adjacent components as a minimum. Our elastomeric bearings increase the value of the building by avoiding structural damage and eliminating renovation and maintenance costs. Static elastomeric bearings permanently transmit forces, twists and displacements into adjacent components without causing damage.

The bearings’ extremely high load capacities allow cost-effective, filigree structural designs to be built. Elastomeric bearings do not require maintenance and do not need to be replaced if correctly dimensioned and installed. The designers also ensure there is extra capacity in the material to absorb unforeseen loads. The service life of construction bearings is equal to the service life of adjacent components as a minimum. Our elastomeric bearings increase the value of the building by avoiding structural damage and eliminating renovation and maintenance costs. Static elastomeric bearings permanently transmit forces, twists and displacements into adjacent components without causing damage.

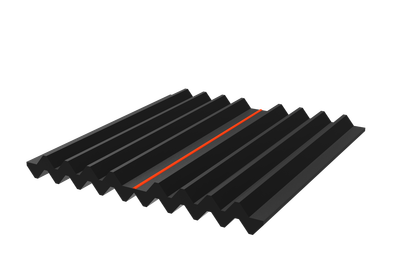

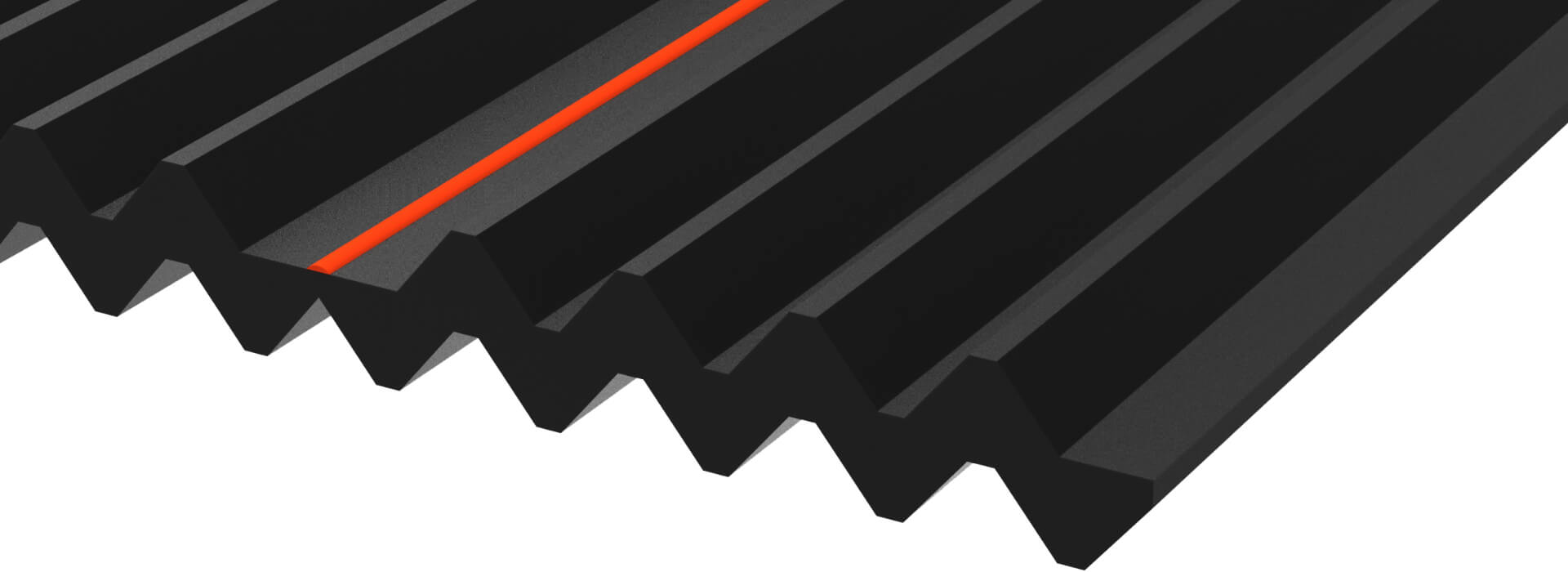

Non-reinforced elastomeric bearing

Short description

The bi-Trapez Bearing provides highly effective insulation against impact sound and vibrations and is permanently elastic in case of component rotation. This bearing is primarily used for structural members of all types and for impact sound mitigation in stair and landing components.It is a non-reinforced elastomeric bearing with trapezoidal profiling on both sides and a shape dependent load capacity of up to 17.4 N/mm². The main component is an ageing resistant EPDM elastomer material with a hardness of 67 Shore A. The material is weather and ozone resistant. The material is quality controlled.

Approval no. Z-16.32-455, issued by DIBt Berlin.

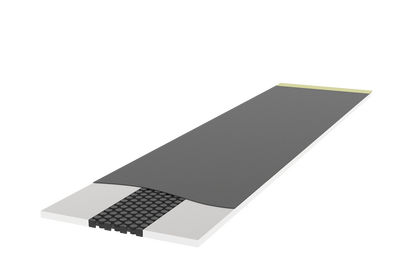

Short description

The Cigular Slab Bearing can absorb shear deformations in any direction including those in the longitudinal direction of the wall that pose the greatest threat to brickwork and are the cause of shear cracks in ceiling slabs.The non-reinforced, profiled elastomeric bearing has a load capacity of up to 1.5 N/mm² and is available in a thickness of 10 mm. The main component is an ageing resistant EPDM elastomer material. The material is weather and ozone resistant. The material is quality controlled.

Approval no. Z-16.32-479, issued by DIBt Berlin

Short description

The Cigular Slab Bearing EcoLine 2.0 can absorb shear deformations in any direction including those in the longitudinal direction of the wall that pose the greatest threat to brickwork and are the cause of shear cracks in ceiling slabs.The non-reinforced, profiled elastomeric bearing with a sheathing made of Ciflamon has a load capacity of up to 1.5 N/mm² and is available in different core widths: 35, 60, 83 and 106 mm.

With the Ciflamon coating, the F90 requirement is fulfilled in accordance with fire protection assessment No. 3799/7357-AR, provided that the embedding on both sides after installation is at least 30 mm wide.

The total width of the product is 300 mm and the bearing thickness is 10 mm. The main component is an ageing resistant EPDM elastomer material. The material is weather and ozone resistant. The material is quality controlled.

Approval no. Z-16.32-479, issued by DIBt Berlin

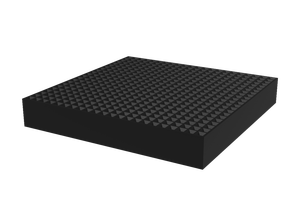

Short description

The Compact Bearing CR 2000 has a honeycombed bearing surface, which results in an even distribution of stress over the cross section. The transverse and splitting tensile stresses produced in the adjoining components are reduced compared with smooth elastomeric bearing plates.It is an unreinforced, profiled elastomeric bearing with a shape-dependent load capacity of 20 N/mm² (characteristic value). The bearing is available in various thicknesses. The main component is an ageing resistant CR material with a hardness of 70 ± 5 Shore A. The material is weather and ozone resistant.

The period of validity of the old authorisation has expired and a new one has been applied for.

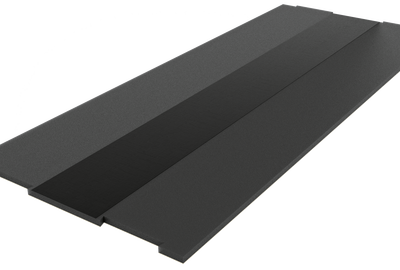

Short description

The Compact Bearing S 65 is a deformation bearing and is used in all areas of construction as permanently elastic articulating connection element.The unreinforced elastomeric bearing has a load capacity of up to 14 N/mm² depending on shape and is available in various thicknesses. The main component is an ageing resistant EPDM elastomer material with a hardness of 65 ± 5 Shore A. The material is weather and ozone resistant. The material is quality controlled.

Approval no. Z-16.32-474, issued by DIBt Berlin

Short description

The Compact Bearing S 70 is a deformation bearing and is used in all areas of construction as permanently elastic articulating connection element.The unreinforced elastomeric bearing has a load capacity of up to 21 N/mm² depending on shape and is available in various thicknesses. The main component is an ageing resistant EPDM elastomer material with a hardness of 70 ± 5 Shore A. The material is weather and ozone resistant. The material is quality controlled.

Approval no. Z-16.32-477, issued by DIBt Berlin