SPECIAL PRODUCTS

THE PERFECT SUPPLEMENT FOR YOUR SYSTEM

THE PERFECT SUPPLEMENT FOR YOUR SYSTEM

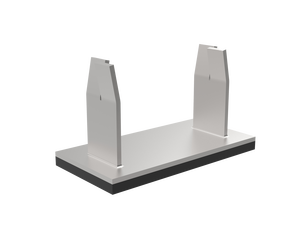

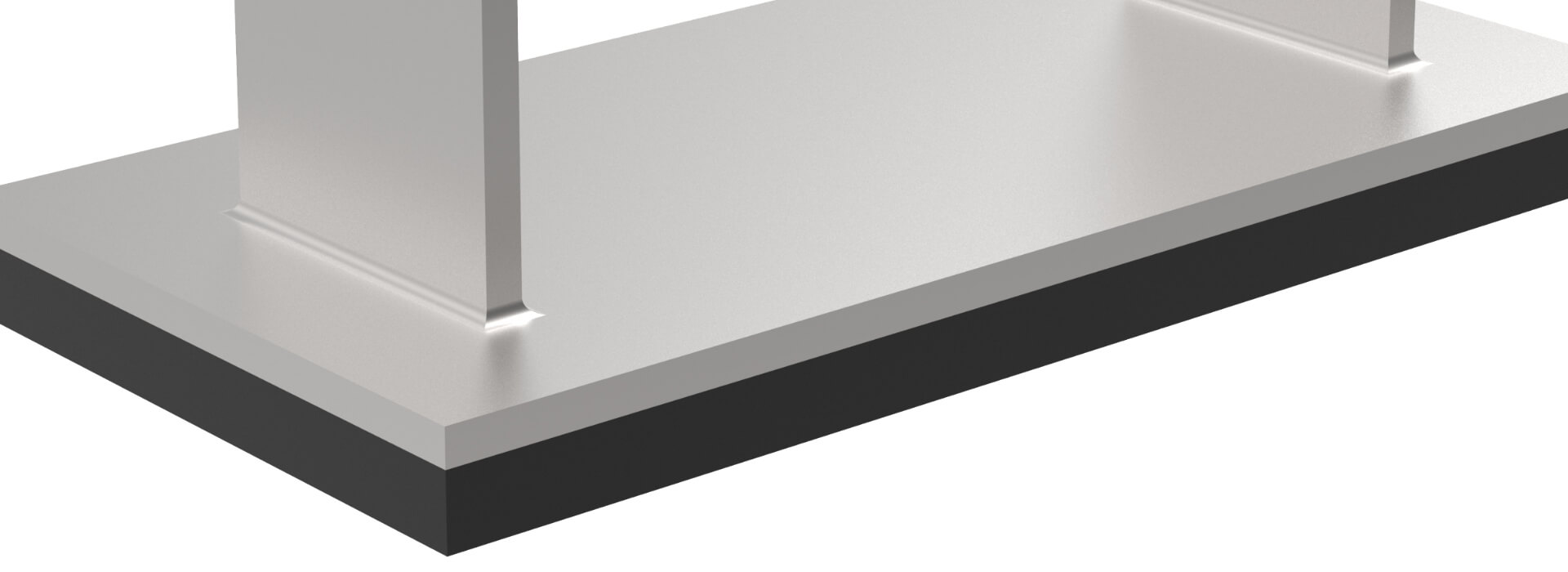

Directional control bearing

A track bed structure frequently used in railways, tramways and underground railways is ballastless track, where a rigid upper structure consisting of concrete or asphalt track slabs replaces the usual ballast and railway sleepers. Such track systems may seem rigid and immobile at first glance. Yet even ballastless tracks move, at least to a limited extent as part of their design. This is because of internal restraints due to fluctuations in temperature, external forces applied by trains, particularly when they brake or accelerate, and lateral forces (centrifugal forces) when trains go round curves. Movements caused by these forces need to be restricted so that the track stays in its intended position.Directional control bearings are special bearings designed to absorb the forces described above and restrict movement, thus providing track position protection in ballastless track systems. These bearings are sturdy rubber-metal moulded parts made of weather-resistant stainless steel and a high-quality, long-term-resistant rubber compound, which is vulcanized and force-fitted onto the stainless steel in the factory. The bearing rear features stainless steel anchorages, which can be easily concreted into side walls of track troughs or similar to protect the joint between the side wall and the sliding support plate, for example.

EPDM shear cam pads

A track bed structure frequently used in railways, tramways and underground railways is ballastless track, where a rigid upper structure consisting of concrete or asphalt track slabs replaces the usual ballast and railway sleepers. As a general rule, the upper and lower structures are separated by a layer which is elastic to a lesser or greater extent. Cams, humps or similar components are fitted to the substructure, protruding into the track slab structure to transmit shear and constraining forces from the track and into the substructure. The cams are then fitted with EPDM shear cam pads, which allow a "soft" absorption of thrust and constraining forces after the track slab is concreted into position. This avoids rigid connections between the upper and lower structure, which could otherwise cause damage to the entire track. As with all elastic bearings, it is important to ensure that fresh concrete isn’t accidentally poured inside the pad joint, for example. Otherwise, this will create a rigid joint after the concrete has hardened, thus neutralising the effect of the elastic joint. Suitable Calenberg special bearings can be supplied in dimensions adapted to the specific project requirements and in thicknesses of 5, 10, 12.5, 15 and 20 mm. The pads have a load capacity up to 15 N/mm², depending on the format, and are made of a high-quality rubber material that remains resistant to ageing, high load and elastic for the track’s entire service life. EPDM shear cam pads prevent damage and help to reduce track maintenance costs.SPECIAL PRODUCTS

Description, application

Special bearing for the absorption of shear- and restraint forces in slab track systems. Can be supplied in dimensions adapted to the specific project requirements and in thicknesses of 5, 10, 12.5, 15 and 20 mm. The bearing has a load capacity up to 15 N/mm², depending on the format.Features

- Premium quality rubber material

- Highly elastic and resilient

- Ageing-resistant

- Prevents damage to ballastless track

- Easy installation

- Reduction in maintenance costs for track system

Description, application

Special bearing for securing horizontal track alignment or absorption of horizontal forces in slab track systems. Delivered as stipulated on data sheet; differing project-specific dimensions may be available on request.Features

- Sturdy rubber-metal moulded part

- Weather-resistant stainless steel

- High-quality vulcanised rubber compound

- Built-in part, light in weight

- Easy installation

- Secures track position