UNDER BALLAST MATS

FOR HEAVY HAUL TRANSPORT

FOR HEAVY HAUL TRANSPORT

Heavy Haul transport

Rail freight transport is confronted with various challenges: The railway infrastructure has to cope with very high axle loads as well as increasing travel speeds without any problems and without limiting the service life of the superstructure. Reliability, performance and economic efficiency of the railway system should be guaranteed or even increased.

For this purpose, Calenberg has adapted its product range with Ciprotec 1515 and USM 4015 accordingly in order to cope with heavy axle loads in ballasted tracks. These permanently elastic sub ballast mats increase service life, availability, reliability, ease of maintenance of the superstructure and thus reduce effort and expenses required for track maintenance. In addition, the products provide optimal vibration protection for the benefit of residents.

Ciprotec 1515 and USM 4015 are tested up to 35t axle load (Track category TC 4).

For this purpose, Calenberg has adapted its product range with Ciprotec 1515 and USM 4015 accordingly in order to cope with heavy axle loads in ballasted tracks. These permanently elastic sub ballast mats increase service life, availability, reliability, ease of maintenance of the superstructure and thus reduce effort and expenses required for track maintenance. In addition, the products provide optimal vibration protection for the benefit of residents.

Ciprotec 1515 and USM 4015 are tested up to 35t axle load (Track category TC 4).

Features

- improved track performance

- extended service life

- reduced life cycle costs

- increased elasticity of the superstructure

- higher track position stability

- increased ride comfort due to vibration isolating properties

UNDER BALLAST MATS FOR HEAVY HAUL TRANSPORT

Description, application

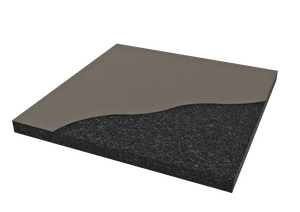

The two-layered product Ciprotec 1515 consists of an elastic layer made of 100% recyclable elastomers and a geotextile (GRK 5) protective layer on its upper surface. Ciprotec helps to reduce environmental impact and conserve resources.The composition of the elastomer layer from bonded rubber fibres as well as different mat thicknesses and the geotextile protective layer have been successfully tested at the Technical University of Munich in accordance with DIN EN 17282 for axle loads of up to 35 tonnes.

This combination provides an ideal solution for heavy haul transport to achieve the required elasticity and position stability in the ballast superstructure.

Description, application

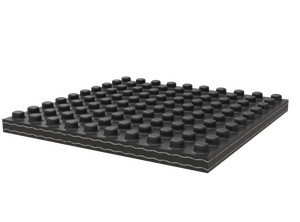

Made of synthetic and natural rubber, these specially designed USM model with its unique shape is tested in this design and stiffness for axle loads up to 35t. Like the other USM models, the mateffectively reduces vibration and shock emissions from rail-bound traffic. The USM 4015 is also suitable for heavy goods traffic to ensure the elasticity and positional stability of the ballast superstructure, especially when solutions with extensive drainage underneath the mat are required.

The USM 4015 is manufactured using high-grade rubber blends. It have a high mechanical load capacity and is permanently weather-resistant. The mats absorb virtually no water, excel thanks to its high electrical insulation resistance and provide drainage on the mat level.

The USM 4015 is suitable for both ballasted and ballastless track systems. This model with a greater stiffness is also used as what are known as transition mats to adapt stiffness in different types of adjoining track sections.

The test for the heavy haul transport is carried out according to DIN EN 17282 category TC 4 with increased requirements and successfully passed.